The

professionals choose

"HOT END".

During the last 15 years there

is a tendency for repositioning of leading glazed windows producers from

traditional multi-operational technology for pressurization of the glazed glass

to single operational technology using flexible spacer. That technology ensures

very good energy saving indicators and higher production efficiency.

Developed by the American company TruSeal Technologies Inc. more than 25 years ago the pressurization system has first appeared in North America and still has solid positions on the world joinery production market.

The "hot end" system has many advantages compared to the traditional multi-operational technology for production of glazed windows:

- second pressurization is not necessary;

- production of windows with different shapes and sizes without using additional equipment;

- low energy and labour costs;

- big production premises and warehouses are not necessary;

- high heating and

pressurization properties;

- increased life of thewindow

(about 30 years).

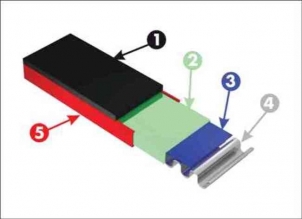

The use of flexible

pressurizing system in the windows production simplifies considerably the

production process and does not require high costs, warehouses, production

premises and many employees. Pressurization

of the window is done only by one operation. Therefore, the technology can

be used in small warehouses with production capacity 20-30 windows per day as

well as in higher volumes production with production capacity 1500-2000 windows

per shift.

Production line using horizontal roll press and hand application of the spacer allows production of windows with random

shape without loosing time.

The

extremely simplified process,

lack of waste, environmental friendly production and practically unrestricted

opportunities for the production of special constructions make the TruSeal technology along with the use of flexible spacers, attractive and

desired by the producers.

Windows using flexible

spacers, often called "hot end system", are widely used in

industrial, public and residential construction, incl. for energy saving,

triplex, reflective and decorative glasses as well as in transport and fridges.