The product range of the company has widened during the years and nowadays it could satisfy the demands of most pretentious clients. We are one of the first to adopt the innovations in our sector which makes us market leaders in the country.

As a confirmation of the abovementioned we would like to stress the fact that in 2009 Cheh Plast was the first company in Bulgaria which produced PVC joinery GENEO series, one revolutionary profile system of REHAU suitable even for passive houses. During the second half of 2009 Cheh Plast is representative of Eurostill for assembly of interior doors, garage doors and the rest of their product range.

...products

Home...Maintenance of joinery, assembly, services for automatic doors, production of glasses.

...services

Home...

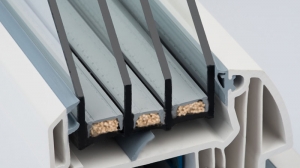

Glass is construction of two or more glass, between which there is an air gap that occurred with different size spacers and hermetically closed.

...glasses

Good glass must be double barrier. One barrier in the glass is butylene affixed on both sides of the spacer and the second is silicone, polysulfides or tiokolat filling the space between the panes and the spacer. In operable windows can not penetrate water outside and inside the closed moisture with air in making it is absorbed by molecular sieve, which is filled spacer. Thus, between the panes can not be formed condensate.

Glazing may be several types and for different requirements: low-emission, energy saving double glazing, triple glazing, insulation, sound insulation, argon.

Home / Products...As a demonstration of its innovative spirit, Cheh Plast Ltd. launched into exploitation a new line for production of window glasses (look at the pictures below) with flexible spacer DuraSeal of the American company TruSeal Technologies.

Assembly and adjustment of the press, working table and applicator for setting the flexible spacer was made with the support of the Commercial Director for Russia and Belarus - Viktor Sirichev who showed his indisputable technical knowledge about the spacer, the technology and line machines. After the assembly and adjustment which took place with active participation of workers and employees of the company, Mr. Sirichev trained the workers in department "Window glasses" for the different operations related to production of window glasses with the new spacer. Despite of their long experience in the department, workers, technologists, production director and the manager, were watching the demonstration because the technology is different from the one used so far and is almost unknown in Bulgaria. Indisputable advantages of this technology using DuraSeal and DuraLite ( we will start to use the last one in short time) which is often called "hot end", could be summarized in two directions.

The first is the decreased number of operations during the production of window glasses (4 operations) compared to the standard (8 operations) and secondly, these are the indisputable exploitation advantages of TruSeal products - DuraSeal and DuraLite compared to other known spacers and mostly the aluminium one.

Spacers DuraSeal and DuraLite have been examined in the production of TruSeal Technologies in the laboratory of TruSeal as well as in independent laboratories. The tests have confirmed notable thermal characteristics and permanence compared to indicators of analogous spacers. By using multi-component structure and unique processes, TruSeal has developed a family of spacers having superb life with excellent thermal characteristics. All of the abovementioned along with the simplicity of application and lack of secondary pressurisation, makes the spacers on Dura-platform of TruSeal the best alternative to all other spacer regarding quality and price as well as better productivity and reliability.

DuraSeal saves 50% more energy than ordinary U-shaped metal spacer and 90% more than an aluminium spacer. In DuraLite the corrugated aluminum separator is replaced by polycarbonate which reduces the heat diathermancy and makes DuraLite leader among the other systems "hot end" type. Due to its air-heated structure TruSeal spacers increase the temperature at the end zone of the window glass by 4-6 oC, which increases the total temperature of the window glass and ensures additional comfort and heat in the house. By increasing the temperature in the end zone of the window glass the possibility for condensation is decreased by 80% and it completely excludes freezing and formation of frost at the end of the window glass. The DuraSeal system allows shorter time for argon fill of the window glass (3.5 seconds instead of 2 minutes) which optimizes the production time for the windows. Thanks to the pressurization properties of the spacer the system retains argon, while maintaining thermal properties of the window during its exploitation. The use of window glasses using DuraSeal and DuraLite is possible in all areas with severe climate. For more than 15 years pressurization systems have been used in the Far East and more than 10 years - in Ural and West Siberia. One of the advantages of the flexible pressurization system is the presence of only one separable angle which is sealed at the end of the assembly. All other angles are whole which ensures reliable protection against moisture and perfect permanency.

There is a sustained tripartite moisture-protective barrier entering in the structure of the flexible DuraSeal and DuraLite system as an additional protection against penetration of water vapor. Padding plate provide The main feature of the spacer TruSeal from other systems is vlagopoglashtashtiya smooth laminated layer in the composition of which is included desiccant (molecular sieve) with high absorption capacity, providing high dew point.s additional strength, durability and sustainability. The main feature of the spacer TruSeal which distinguish it from other systems is moisture absorbing smooth laminated layer in the composition of which is included desiccant (molecular sieve) with high absorption capacity, providing high dew point. The moisture absorbing layer connects the rest of the moisture in the window glass, keeps it during its entire exploitation (more than 30 years) and prevents the fogging of the glass from the inside. Unique hermetic DuraSeal and DuraLite do not contain acrylic and other additives, bursting under the influence of UV-rays. Due to that, it keeps high adhesion properties and significantly reduces the rate of moisture penetration. The spacers have an adhesive layer with best indicators for resistance to moisture penetration compared to all other windows. P1 tests conducted in independent certification laboratory in the Netherlands showed that under strong influence of UV-radiation in different temperature regimes (from -70оС to +120оС), adhesion of the pressurization has remained constant for 44 weeks. Moreover, the distance between the glasses has changed in the range of 0.02%. Waterproofing layer also serves to retain inert gases such as argon and krypton. DuraSeal and DuraLite spacers and are fully compatible with inert gases and have excellent characteristics for retaining the gases. Adhesive layer and hermetic are an integral part of the spacer system, so there is no need to use a second barrier of polysulphide, polyurethane or butyl.

As a conclusion to all superlatives can be added that spacers with DuraSeal and DuraLite are the most appropriate for passive and energy saving buildings which are targeted by Cheh Plast as the future of Europe and the world.

...new line for window glasses with flexible spacer

Home / News...The company produces certified glasses (Certificate No. 89427 by Stacione Spreimentale del Vetro, Italy), for its own purposes as well as for colleagues, producers of aluminium and PVC joinery.

The glasses of the company have CE mark since November 2009. This mark is compulsory according to BDS EN 1279-1 and 1279-2 from 2006 and for doors and windows it is compulsory since 01.02.2010 according to BDS EN 14351-1. The glasses are produced on a modern line by new machines of Italian companies implemented in January 2006. Because of the production of low-e glasses with soft coat, for the purposes of glass cutting and taking off the soft coating from the perimeter of the glasses, we bought table for cutting with CNC control from Z.BAVELONI - Italy. The product range is wide and you can obtain information about it from section "Products", subsection "Glasses".

...production of glasses

Home / Services...This is how the ready window glass with flexible spacer DuraSeal looks like. You can see the belt made of aluminium, ensuring immobility of the spacer and the lack of second barrier.

...window glasses with duraseal

Home / News / New line for window glasses with flexible spacer ...

Cheh Plast Ltd., is a certified manufacturer and authorized Rehau partner. Cheh Plast offers production and installation of aluminum joinery, German PVC joinery, suspended facades, ventilated facades with composite panel, ceramics, HPL and ethernet, glass doors and windows, winter gardens, blinds, polycarbonate roofing.

The company was established in 2000 and is managed by engineer Dimitar Ivanov up to this day. The company now employs 67 professional engeneers and workers. The activity develops on 12,100 sq.m. property with 2900 sq. m. built-up area and is concentrated in 4 workshops for PVC joinery, AL joinery, glazing and metal welding workshop. The company works with PVC profiles REHAU - Germany and aluminum joinery of the companies ETEM, SCHUCO, REYNAERS and ALUMIL. For the construction of curved facades SCHUCO and ETEM profiles are used. Since 2004, Cech-Plast Ltd has been involved in the manufacture and installation of ventilated facades of composite material (ALPOLIC and ETALBOND), ceramics, HPL and wood as building lining as well as roofing structures made of glass and polycarbonate boards. These are products that we had to implement in order to meet customers' requirements for complex building closures. At the beginning of 2006, a glass workshop equipped with new machines of the Italian companies Poliglas and Z.Baveloni, which produces glasses for own use and sale, works with a low-emission glass - soft emission. In 2016, the company completely changed and renewed the aluminum and PVC production workshops with CNC machines, which doubled the production capacity of the company. The equipment is mainly made by German manufacturers URBAN, GRAULE, THORWESTEN, ROTOX and ELUMATEC, as well as Italian ITALMAC.

Clients of Cheh-Plast Ltd. can be defined as more demanding and although the company is based in the small town of Vratsa, its production is well known throughout the country. The company has offices in Sofia, Lovech and a representative in Burgas who have been working successfully for more than 5 years. Since the beginning of 2003, the company has been a certified manufacturer, since it has been certified by the Austrian and German representatives of the company as a quality certificate for the production of PVC joinery REHAU, and since May 2009 has been "Authorized REHAU partner". All this is due to the compactness of the company and the excellent professional training of the staff. Thanks to the above mentioned, Cech-Plast Ltd. Became a well-known name in the cities: Sofia, Lovech, Burgas, Mezdra, Sevlievo, Varna, Sozopol, Kozloduy and abroad (Raiffeisenbank, Belgium, France and Austria). The company definitely has experience in working with banks as clients. "Cheh-Plast" Ltd. has made over 200 branches of Raiffeisenbank as well as separate branches of UniCredit Bulbank, Postbank, Alpha Bank, Piraeus Bank, Cooperative Bank and Allianzbank.

"Cheh-Plast" Ltd. is a member of "Bulgarian Doors, Windows and Facades" Association from 2004. The Association includes more than 100 companies from the builders branch, who are positive, tat the only way to achieve results matching the client’s demands is to invest in the business itself.

In 2016 and 2017, the company invested over 3 million Bulgarian levs in a new hall, machinery and equipment. In order to have the latest in the industry.

To meet the new requirements of architects and investors, Cheh-Plast Ltd. does not miss professional exhibitions specializing in the branch of the joinery manufacturers in Nuremberg and Munich, Germany, and to keep in touch with the latest innovations its regularly sending its experts to Thessaloniki, Greece and Istanbul, Turkey.

...about us

Home...Hotels

- SPA Hotel Meditsus city. Varshetz - suspended facade system Е 85, PVC joinery, composite panels Etalbond, automatic door

- RING hotel city. Montana - PVC joinery, metal structure with thick roof shingles, automatic door

- Evrohoteli AD, Hotel Gorna Banya - PVC and AL joinery

- ET Invest - V.C., Burgas - Hotel Prestige, z.k. Lazur - PVC, AL joinery

- Road motel opposite SHELL, Aytos "Roadstar" - PVC joinery

- Balkanbas Hotel, Sarafovo, lead contractor - PVC joinery

- Hotel in Nesebar, assignor is Drima Ltd. - PVC joinery

- Hotel complex Chaika Vratsa - PVC and AL joinery, glass doors and windows, automatic door and garage systems GEZE

- Hashove Hotel Vratsa - PVC and AL joinery

- Lazur Hotel Burgas, z.k. Lazur - PVC, AL joinery and suspended facade

Bank Offices

- Raiffeisenbank - over 190 branches in the whole country

- Bulbank AD office Montana, AL joinery + bank security /armoured glasses/, lead contractor

- Raiffeisenbank Burgas branch - suspended façade and internal AL barriers

- Biohim AD, branch Customs Lom and branch Vratsa - AL joinery

- Raiffeisenbank Kosovo, Prishtina - AL joinery, ETALBOND

- Raiffeisenbank Kosovo, Teranda - AL joinery

- Raiffeisenbank Kosovo, Raovets - AL joinery

- Post Bank Vratsa - AL joinery, ETALBOND

- Alfa Bank, branch Vratsa - AL joinery, suspended façade

- Union Bank, branch Vratsa - AL joinery - subcontractor of Lintel

- Bulbank, branch Vratsa and branch Montana - AL joinery

- Piraeus Bank, branch Vratsa - ETALBOND

- Central Cooperative Bank, branch Vratsa, Mezdra and Byala Slatina - AL joinery and ETALBOND

Public Buildings

- PENNY Plovdiv, residential district Trakiya - suspended facade, aluminium joinery and automatic doors

- LIDL Plovdiv, residential district Trakiya suspended facade, aluminium joinery and automatic doors

- Casino in Sofia, residential district Levski - AL joinery, ventilated facades with ETALBOND and glass constructions

- MALL "Danube" in Ruse - roof glazing, suspended facades and ventilated facades with ETALBOND

- BILLA Sofia - Orlandovtsi - suspended facade, aluminium joinery, glass doors and windows

- BulARKO AD - Sofia

- Nadin AD, administrative building in Sofia, residential district Suhata Reka - PVC and AL joinery

- Creditreform Bulgaria Ltd. - administrative building in Sofia next to 3rd urban polyclinic, Ulitsa na uslugite Str. - PVC and AL joinery, external rolling PVC persiennes

- NPP Kozloduy, 5th and 6th block, subcontractors DPSV Vratsa District - AL joinery

- NPP Kozloduy, 5th and 6th block, lead contractor - automatic door

- Pedestrian trestle hill 5th floor between ILK, 5th and 6th block of NPP Kozloduy - subcontractor AESP - PVC and AL joinery

- Police department Vratsa

- NCCR, Vratsa District - AL and PVC joinery, lead contractor

- Bus station Sevlievo, "Kometa Bus" - AL joinery, trade representative

- Main Tax Office Sofia - AL joinery and glass doors

- "Auto Plus", Vratsa - showroom + service

- Holcim Bulgaria AD, Beli Izvor, lead contractor - AL and PVC joinery

- Logo Company, Primorsko, residential building, lead contractor - PVC and AL joinery

- Puls-GRP Ltd. Burgas, residential buildings, houses, villas - PVC joinery

- Bulstrad, branch Kozloduy - AL joinery

- Nafteks Engineering AD, Sofia - AL joinery, repairs

- Lukoil, Vratsa, lead contractor - AL joinery

- Lukoil Burgas, lead contractor - AL joinery and ETALBOND

- NPP Kozloduy, supervisor PNF, subcontractor AESP

- NPP, Kozloduy, site Management "Security", lead contractor - AL joinery

- NPP, Kozloduy, 5th block hill 19 - AL joinery

- Regional Inspection Environment, Vratsa, subcontractor of Stroyinvest

- National Telecommunication Company Vratsa, lead contractor

- AED, Kozloduy, HOG

- Sky Group Vratsa, lead contractor - AL joinery trade complex

- Pasat-MN Sofia, lead contractor - AL joinery and glasses

- Universal AD, Sofia - PVC joinery

- Ministry of Interior, Simeonovo residence, lead contractor SST 200 Ltd. - PVC joinery

- Ministry of Interior, Department "MTOSO", investor Simeonovo residence

- V i K, Vratsa - supply of PEH D pipes and shape parts for them

- Boevski 2000, lead contractor - AL joinery

- Danis Ltd. - AL joinery

- Polisan, lead contractor joinery, petrol station in Vratsa

- Poliengineering, Ruse, administrative and residential building - AL and PVC joinery

- L G Petrolium, Ruse, production facility - PVC joinery

- District prosecutor's office, Botevgrad, subcontractor of NCCR - AL joinery

- "Investigating custodies" Vratsa, subcontractor "Stroitelna Kompaniya" - AL and PVC joinery

- Traffic Police, Vratsa, lead contractor - AL and PVC joinery

- Technopolis Vratsa - AL joinery, suspended facade, automatic door, ETALBOND

- BILLA Vratsa, Montana - suspended facade, AL joinery, anti-fire doors JANSEN, automatic doors - subcontractor of Jung Ltd.

- BILLA, Pernik - construction facade, AL joinery - subcontractor of Jung Ltd.

- Satelit Ltd., office building, AL joinery, 10 mm glass, ETALBOND - lead contractor

- T-Market - suspended facade, AL joinery, PVC joinery - lead contractor

- Villa "Teva", Ledenika - PVC joinery

- POK Ledenika of NPP Kozloduy EAD - PVC joinery, metal constructions - lead contractor

- Astroko AD, residential complex "The Tower Castle", "Grand Royal", Bansko

- Korekt Ltd., Vratsa, residential buildings in Sofia and Vratsa

- Komet Electronics Sofia - administrative building

- Peshkovski & Karamelski law office - administrative building in Vratsa

- District Court, Vratsa- PVC Winows

...portfolio

Home...GENEO is a new REHAU PVC profile made of high technology material (RAU-FIBRO) used in the aircraft engineering and Formula 1 with strengthened filaments allowing high degree of profile's core stability. It is PVC joinery extremely suitable for energy efficient and passive houses:

- Six-chamber profile;

- Building width: 86 mm which allows the use of highly effective triple glazed glasses;

- Heat isolation of the profile (Uf) for windows corresponding to the standard for passive house;

- Noise insulation, class noise insulation (VDI 2719): to SSK 5 (glazed glass 50db = Rw, P 47db);

- Elements without reinforcement could be built with the following dimensions: 2100 mm height and 1100 mm width.The result is a new dimension in the production of windows, revolutionary connection between high technology REHAU material RAU-FIPRO® and innovative profile construction: REHAU GENEO.

Unsurpassed Heat Isolation

GENEO is the best energy window system with building width 86 mm which is currently on the market. The most energy efficient windows in the respective class are realized with the GENEO profiles. They create the cozy climate which the construction entrepreneurs have always wanted. The secret is that the new system meets all energy requirements in a flexible way and it is not necessary to make compromises related to better noise insulation or more effective burglary protection when purchasing it. With GENEO the windows are manufactured with noise insulation class 5, and for burglary protection - with class wind resistance 2, without steel reinforcement and at the same time the unique heat isolation properties are used in their full capacity. In the fully reinforced by strengthened with filaments profile construction, the steel can be dropped off which eliminates the need of the unavoidable so far thermo-bridges. In case of standard building width, the system with middle insulation and offered as an option thermo-modules reaches values of heat isolation up to the standard of the passive houses. For example with the new windows GENEO MD plus a house owner could save up to 1.341 litres naphtha per year – equal to around 1.006 € – and at the same time to relieve the environment with 3 ½ tons CO2.Unique, innovative and future oriented.

...geneo - for energy efficient and passive houses

The specially developed for GENEO high technology material RAU-FIPRO offers unknown till now advantages from the moment of window construction. The strengthened by filaments materials have proved their qualities years ago in the hardest aircraft engineering and Formula 1 conditions. In GENEO that material is placed in the core of the profile and takes care for the excellent stability and torsion resistance. Similar systems with steel reinforcement are up to 40% heavier than the fully reinforced GENEO profiles. In simple words, this means faster, not complicated and easy work during the manufacturing, transportation and assembly. The patented "Integrated Reinforcing System IVS", supplied with integrated channels for screwing and additional strengthening cross-elements, ensures maximum stable fixation of the screw compounds and huge basic stability of the profiles. All these qualities don't mean that processing company has to make big investments. The GENEO profiles can be processed only with the available machines and usual processes as for example it is in welding.

Home / Products / Joinery / PVC joinery...On 21.04.2011 on the territory of administrative and production facility of Cheh Plast in Vratsa the traditional annual seminar of the company with all employees took place. Besides the employees who had to exchange experience gained during the year on exhibitions, fairs, business trainings, specialists from our supplying companies were invited as well. This year they were:

- Mr. Zahariev - representative of AGC for Bulgaria - leading glass producer worldwide;

- Mr. Pachev - manager architecture systems in Stilmet AD - Bulgarian leader in the area of aluminium profile systems;

- Mr. Mondeshki - specialist profile systems in Rehau Bulgaria - Cheh Plast has been working with these profiles since the establishment of the company in 2000.

Mr. Zahariev presented to the audience new and not so new but unused by us products of the leader in glass production - AGC. Attractive decision "Top 1,0" which achieves notable indicators related to heat transition from Ug=1,0 W/m2 K, successfully regulates the transition of sun rays with solar factor g=36% and the ability to accept the touch of the surrounding environment (profile colours, colour of next facade) impressed everybody. The attraction was demonstration of advantages and strength indicators of the painted glasses Lacobel of AGC. There was a short movie with examination of Lacobel agglutinated to plasterboard with round shot 0,5 kg from 4,5 m height which could not break the glass. Similar examination but with rubber hammer was made by a volunteer from the company and again the attempt was not successful despite of the efforts and force used. The objective was demonstration of safety in using Lacobel in bathrooms, kitchens, toilets and other premises and the interesting colour range as well as lack of gaps make them preferred for more clients.

Mr. Pachev told us in details about the changes and technical improvements of the suspended facade E85 which premiere was in the beginning of 2010. What was seen and explained by Mr. Pachev showed the deep work of the Stilmet engineers with use of feedback from the assembly companies that have already used the suspended facade on sites.

Extremely interesting for the whole audience was the presentation of Mr. Pachev related to the newest openable window system E75, meeting the newest requirements for heating, functionality and aesthetics. He pointed out the advantages of this system as elegant straight vision with assembly width of 75 mm, heat transition coefficient Uf from 1,1W/m2K, polyamide tapes from 39 mm, coextruded central pack and additional isolator in the thermal interruption zone. The employees in workshop "Aluminium joinery" and technologists from the company asked questions and asked about details for assembly and link between the case and wall because even if the system is new, we have already completed some orders with window system E75. Mr. Pachev showed specially developed profiles used for water resistant and steam diffusion tapes, for link with heat- and hydro-isolation system of the building.

Last but not least Mr. Mondeshki attracted the audience before the lunch break with new Rehau products launched on the market during the last year.

After a brief exposé, related to the material from which profiles are produced and its physical and mechanical properties and its safety for humans, Mr. Mondeshki introduced to us the newly developed GENEO profiles.

With them we can satisfy our customers’ desires and produce doors, sliding with lifting, that up to now we made with Brillant Design (five-chamber system 70 mm. construction width).

The need for these new profiles appeared with the enhanced search of windows for passive houses in Western Europe and in Bulgaria, and the passive houses’ front doors and large glazed and opening areas were not feasible without GENEO newly developed profiles.

The representative of Rehau Bulgaria Ltd paid greater attention to the profile system EURO 86, which copies the configuration of GENEO profile system, but the material is traditional.

Euro Design 86 is a reasonable cost solution for low-energy and conventional buildings, because of the heat transfer coefficient of the frame Uf of 1,2 W / m² K (with reinforcement without supplements) and rabbet construction for optimal uptake of triple glazing to 53 mm., more frequently recommended and implemented to the customers.

After one-hour cocktail break in order to refresh ourselves and discuss our experience with the lecturers, the afternoon session of the seminar began. During this session, six employees -Prof. P. Georgiev, Prof. Is. Neshev, Ivaylo Mitov, Eng. V. Galabov, Yoto Yotov and Prof. D. Ivanov - shared what they have seen and learned on their visits to workshops, trainings and fairs abroad. They all had prepared numerous photos, which illustrated their talks.

In the end, we discussed the plan-program of the company for the next 3 years and did analyze the Corrective Preventive Action (CPA) with repeated mistakes, paying attention to all the employees in order to minimize them in the future.

...cheh-plast conducted the traditional annual seminar

Home / News...

Our partners