Declaration can see Here

...performance declaration gealan s9000 glazed low e + argon + low e

Home / CE and Performance declaration......

performance declaration brillant design glazing 24mm chemical mat + argon + low e

Home / CE and Performance declaration......

performance declaration brillant design glazing low e + 33,2 + argon

Home / CE and Performance declaration...

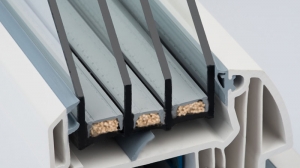

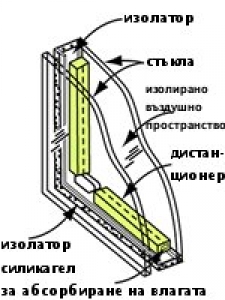

Glass is construction of two or more glass, between which there is an air gap that occurred with different size spacers and hermetically closed.

...glasses

Good glass must be double barrier. One barrier in the glass is butylene affixed on both sides of the spacer and the second is silicone, polysulfides or tiokolat filling the space between the panes and the spacer. In operable windows can not penetrate water outside and inside the closed moisture with air in making it is absorbed by molecular sieve, which is filled spacer. Thus, between the panes can not be formed condensate.

Glazing may be several types and for different requirements: low-emission, energy saving double glazing, triple glazing, insulation, sound insulation, argon.

Home / Products...As a demonstration of its innovative spirit, Cheh Plast Ltd. launched into exploitation a new line for production of window glasses (look at the pictures below) with flexible spacer DuraSeal of the American company TruSeal Technologies.

Assembly and adjustment of the press, working table and applicator for setting the flexible spacer was made with the support of the Commercial Director for Russia and Belarus - Viktor Sirichev who showed his indisputable technical knowledge about the spacer, the technology and line machines. After the assembly and adjustment which took place with active participation of workers and employees of the company, Mr. Sirichev trained the workers in department "Window glasses" for the different operations related to production of window glasses with the new spacer. Despite of their long experience in the department, workers, technologists, production director and the manager, were watching the demonstration because the technology is different from the one used so far and is almost unknown in Bulgaria. Indisputable advantages of this technology using DuraSeal and DuraLite ( we will start to use the last one in short time) which is often called "hot end", could be summarized in two directions.

The first is the decreased number of operations during the production of window glasses (4 operations) compared to the standard (8 operations) and secondly, these are the indisputable exploitation advantages of TruSeal products - DuraSeal and DuraLite compared to other known spacers and mostly the aluminium one.

Spacers DuraSeal and DuraLite have been examined in the production of TruSeal Technologies in the laboratory of TruSeal as well as in independent laboratories. The tests have confirmed notable thermal characteristics and permanence compared to indicators of analogous spacers. By using multi-component structure and unique processes, TruSeal has developed a family of spacers having superb life with excellent thermal characteristics. All of the abovementioned along with the simplicity of application and lack of secondary pressurisation, makes the spacers on Dura-platform of TruSeal the best alternative to all other spacer regarding quality and price as well as better productivity and reliability.

DuraSeal saves 50% more energy than ordinary U-shaped metal spacer and 90% more than an aluminium spacer. In DuraLite the corrugated aluminum separator is replaced by polycarbonate which reduces the heat diathermancy and makes DuraLite leader among the other systems "hot end" type. Due to its air-heated structure TruSeal spacers increase the temperature at the end zone of the window glass by 4-6 oC, which increases the total temperature of the window glass and ensures additional comfort and heat in the house. By increasing the temperature in the end zone of the window glass the possibility for condensation is decreased by 80% and it completely excludes freezing and formation of frost at the end of the window glass. The DuraSeal system allows shorter time for argon fill of the window glass (3.5 seconds instead of 2 minutes) which optimizes the production time for the windows. Thanks to the pressurization properties of the spacer the system retains argon, while maintaining thermal properties of the window during its exploitation. The use of window glasses using DuraSeal and DuraLite is possible in all areas with severe climate. For more than 15 years pressurization systems have been used in the Far East and more than 10 years - in Ural and West Siberia. One of the advantages of the flexible pressurization system is the presence of only one separable angle which is sealed at the end of the assembly. All other angles are whole which ensures reliable protection against moisture and perfect permanency.

There is a sustained tripartite moisture-protective barrier entering in the structure of the flexible DuraSeal and DuraLite system as an additional protection against penetration of water vapor. Padding plate provide The main feature of the spacer TruSeal from other systems is vlagopoglashtashtiya smooth laminated layer in the composition of which is included desiccant (molecular sieve) with high absorption capacity, providing high dew point.s additional strength, durability and sustainability. The main feature of the spacer TruSeal which distinguish it from other systems is moisture absorbing smooth laminated layer in the composition of which is included desiccant (molecular sieve) with high absorption capacity, providing high dew point. The moisture absorbing layer connects the rest of the moisture in the window glass, keeps it during its entire exploitation (more than 30 years) and prevents the fogging of the glass from the inside. Unique hermetic DuraSeal and DuraLite do not contain acrylic and other additives, bursting under the influence of UV-rays. Due to that, it keeps high adhesion properties and significantly reduces the rate of moisture penetration. The spacers have an adhesive layer with best indicators for resistance to moisture penetration compared to all other windows. P1 tests conducted in independent certification laboratory in the Netherlands showed that under strong influence of UV-radiation in different temperature regimes (from -70оС to +120оС), adhesion of the pressurization has remained constant for 44 weeks. Moreover, the distance between the glasses has changed in the range of 0.02%. Waterproofing layer also serves to retain inert gases such as argon and krypton. DuraSeal and DuraLite spacers and are fully compatible with inert gases and have excellent characteristics for retaining the gases. Adhesive layer and hermetic are an integral part of the spacer system, so there is no need to use a second barrier of polysulphide, polyurethane or butyl.

As a conclusion to all superlatives can be added that spacers with DuraSeal and DuraLite are the most appropriate for passive and energy saving buildings which are targeted by Cheh Plast as the future of Europe and the world.

...new line for window glasses with flexible spacer

Home / News...

White (4,5 or 6 mm) и white (4,5 or 6 mm) glass or combination between them with total thickness from 15 ÷ 32 mm. That glazed glass has coefficient of heat transition 2,7 W/m2K, which doesn’t meet the requirements in REGULATION No.7 from 15.12.2004 for heat preservation and economy of energy in buildings.

White (4,5 or 6 mm) and low-e (soft coats) glass 4mm with total thickness from 15 ÷ 32 mm with coefficient of heat transition 1,3 W/m2K. That is an energy saving glazed glass which helps us to reach optimum heat isolation of the joinery having in mind that 75 ÷ 90 % of the window surface is glazed glass.

Laminated glass (triplexes 3.1.3, 4.1.4 and 5.1.5 mm) and low-e (soft coats) glass with thickness 16 ÷ 32 mm.

Glazed glasses with external glass in different colours, light reflective – Stop stoll glasses and white, low-e (soft coats) glass.

Glazed glasses with external coloured (blue, green, brown and grey) glass and white or low-e (soft coats) glass with thickness from 15 ÷ 32mm.

Glazed glasses with four-season glass and white or low-e (soft coats) glass with thickness from 16 ÷ 32 mm.

Glazed glasses with Sunergy glass and white or low-e (soft coats) glass with thickness from 16 ÷ 32 mm.

Filling in the chamber between the two glasses with inert gas argon 480.

All abovementioned options can be done by filling the chamber with gas argon which improves the coefficients of the respective types with 0,1 W/m2K up to 0,2 W/m2K.

...double glazing

Home / Products / Glasses ...

In addition to the high heat transition indicators, the triple glazed glass, filled in with glasses with different thickness (no matter what type they are – coloured, low-e, reflective) ensures higher coefficient of noise insulation. Even better is the noise insulation if any of the three glasses is laminated (triplex). The abovementioned glazed glasses are used in regions and streets with dB over the limits.

Possible are all combinations described in the double glazing, considering that difference more that 2mm between the glasses used for the triple glazing is not recommended.

Filling in one or two chambers with argon gas is also possible for us and therefore, will decrease the energy losses.

...triple (two-chamber) glazing

Home / Products / Glasses ...How to choose the glazing?

Glass has established its reputation as material for filling the light holes because of its transparency, excellent resistance to atmospheric conditions and pollutions.

Glazing takes about 90 % from the window surface and therefore, its choice defines the quality of the window such as heat transition and light permeability.

The main criteria for right choice are:

- Purpose of the premises - bedrooms, living rooms, offices etc.;

- Exposure - East, West, North, South;

- Noise - proximity to streets, stations etc.;

- Presence of shadow elements;

- Danger related to burglary.

When glazing places with many visitors, one of the safety glasses should be used - hardened glass or triplex.

Hardened glass has 4-5 times higher robustness against bent than the usual. When braked, it divides into very small pieces which can't hurt anybody.

Triplex does not disintegrate in case of braking. Its advantage is that it protects you against undesired entry and improves the noise insulation.

Which are the constructive window elements?

- Profile case;

- Profile wing;

- Wing;

- Movable divisor;

- Decorative frame bars;

- Water protector.

What is "mullion profile"?

Third option:Both of the fields can be opened and during opening there is a vertical divisor in the middle. This divisor is called immovable.

What is the function of drainages?

PVC profiles don't have the necessary static strength as the aluminium profiles. That's why in one of chambers is put metal reinforced profile with different configuration (closed profile "box", "П"-shaped, "L"-shaped as well as modifications) but they must be zinc coated.

Reinforced profile is joined by self-drilled screws to the PVC profiles in distance of 300-350 mm for the white and 200-250 mm for the coloured profiles.

What is the glazed window?

Glazed window is improved modern option of double glazing.

Its quality can be estimated based on its heat isolation, noise insulation and sun light protection. A glazed window consists of two or more glasses separated by aluminium, plastic or steel spacer (usually perforated). The glasses are agglutinated to the spacer by butyl rubber and the system is sealed hermetically with special material - butyl rubber (hotmelt), silicon, polysulfide or polyurethane. There is a dryer in the spacer which ensures that the air in the space will be dry.

Replacement of the dry air with gas (most often argon) leads to improvement of heat isolation. Good manufactured glazed window can "live" up to 10 years which is its exploitation period. Sealed hermetically windows with silicon are not filled in with gas because the argon can pass through the silicon.

How to protect ourselves from the sun and overheating in the premises?

How to ensure less heat loss during the winter?

How to achieve good noise insulation?Noise insulation becomes better if:

- The window is made of glasses with different thickness, for example 4+5 mm;

- Thicker glasses are used, for example 5 and 6 mm;

- One of the glasses is replaced by triplex (laminated glass);

- Increasing the distance between the glasses.

For special premises - stations, airports etc. are used glasses laminated with special noise absorbing resins.

How to protect our home and office from burglary and entry through the window?

Laminated glass is safe and doesn't disintegrate in case of breaking. It consists of two glasses agglutinated by special resin which keeps the broken pieces into a whole and does not allow passing (similar to the front car glasses). Replacing the usual glass by laminated protects your home or office and at the same time achieves better noise insulation.

Mould?!

Wooden, PVC and aluminium joinery with glazed glass ensure better hermetization than the double glazing. If the external walls have worse insulation than the joinery, especially in panel buildings, the moisture will condense on them. Joinery is part from the whole heat isolation in the premises. Correct and often ventilation is most important for avoiding condensation and mould.

When ordering, choose a construction which allows access to each point of the frame and glass in order to ensure efficient cleaning. If you prefer window which is not accessible and can't be opened before window that can be opened, in order to save money, that could be future loss because of shorter life of the window due to bad maintenance.

The glass must be washed at least once per year in order to be avoided decrease in the transparency due to chemical reactions on the surface.

The so-called self-washable glasses exist - they have an active coating on the surface which helps for transformation of the dirt and its natural washing by the rain....glazing

Home / Advices...

Hotel "Bulgaria" is a business hotel located in the heart of Burgas. With a high of 71m. building of Hotel Bulgaria has 17 hotel floors offering incredible views of Burgas Bay and the old town. The company "Czech Plast" Ltd. participates in the renovation of the hotel and for this purpose, we used a system for AL windows and curtain wall of Reynaers respectively CS 77 standard and CW 50, in RAL C33 color and glazing of 6 mm multifunctional + 4 mm white + 4 mm low emission glass with argon gas.

...hotel bulgaria - burgas

Home / Gallery / Projects...

Our partners